INDUSTRIAL ELECTRICAL

- Well qualified experienced engineers skilled work force to ensure best quality , & and timely manufacturing

- New technological developments are well adopted on regular basis

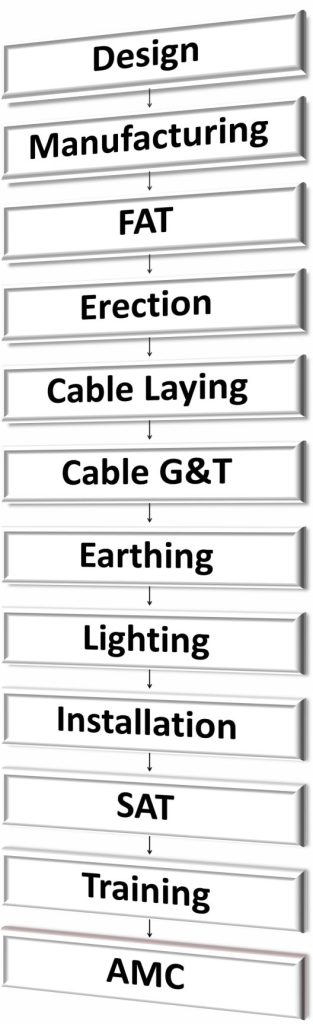

- In-house capability for complete Design, Assembly, FAT site commissioning capability

- Schematic drawing with Solid works, Auto CAD, E-plan in 2D & 3D

- Components from reputed manufacturers

- Automatic busbar bending, punching, cutting machines

- Precise work with Calibrated test equipment

- Quality checks as per ISO 9001:2008 standards

- Labelled and colour coded wiring

- Internal wiring with 660/1100 v Grade Copper wires

- Final paint shade as per IS or client specifications

- EC Grade Aluminium and copper busbar

- Panel doors with fully gasketed for dust/vermin protection

- Rubber Gaskets to meet IP requirement like IP 41/ 42/ 52/ 54/ 55/ 65/ 66

- CRCA & CNC fabricated Powder coated, Seven/Nine Tank Pre-treatment process, rigid, free standing, modular enclosures with superior quality, aesthetics with precise dimensions & sophisticated finish

PCC PANEL

- Maximum nominal current up to 6300A, maximum fault current up to 65KA

- PCC Panel with single / multiple Incomers, Bus coupler with Electrical and/or mechanical interlocking

- Various design like Top/ Middle /Horizontal Bus bar chambers, Al C Bus bar, Top / Bottom Termination

- Single front/ double front Modular / Non- compartmentalized construction

- Exhaust Fan or Louvers for heat dissipations

- Separate chamber for vertical dropper

- Busbar Current rating and Fault withstand capacity with required

- Combination of APFC part with the Panel

- Facilities like DG Incomer with AMF function

- Energy management system

IMCC & MCC PANEL

Intelligent and Non-Intelligent Motor control center

- Maximum nominal current up to 5000A, maximum fault current up to 65KA

- MCC Panel are with Fix / Draw Out type

- Compartmentalized / Non compartmentalized

- MCC Panel with DOL, STAR-DELTA, RDOL starters

- MCC Panel are with various design like Single / Double Front ith type-2 co-ordination

APFC PANEL

- 50 to 1600 KVAR per panel with fault current 65kA

- 4 stage APFC Relay, Master/Slave operation for multiple ~24 APFC Relay

- De-tuned reactor 5.6% 7% 14% / reactor of / Cu Al

- Switching through Capacitor duty contactor / Thyristor

- With / / 415V 440V 525V MPP/APP heavy duty capacitors

VFD PANEL

- 0.5HP to 1800 HP VFD panel with IP41 to IP54 protection, Modular with proper Heat Dissipation

- 0.5HP to 1800 HP VFD panel with customer specific switchgear & protection NEMA 1, 12, 3R, 4 and 4X to IP 20, 21, 31, 41, 42, 54, 55 and IP 56 protection

- 2-Contactor/ 3-Contactor/5-Contactor bypass or changeover switch option

- Input Choke AC/DC, EMI/RFI Filter, Output Choke options

- DBU (Dynamic Braking Unit) and DBR (Dynamic Braking Resistor) with 100% or 150% braking torque for 10%, 15% or 30% duty cycle

- Panel heater, air conditioner

- Individual single VFD, Multiple VFD panel or Common DC bus systems with multiple VFDs, Redundant VFD system

- Various communication options for Modbus / Ethernet/IP / Profibus / DeviceNet / ControlNet

- Modular with proper Heat Dissipation

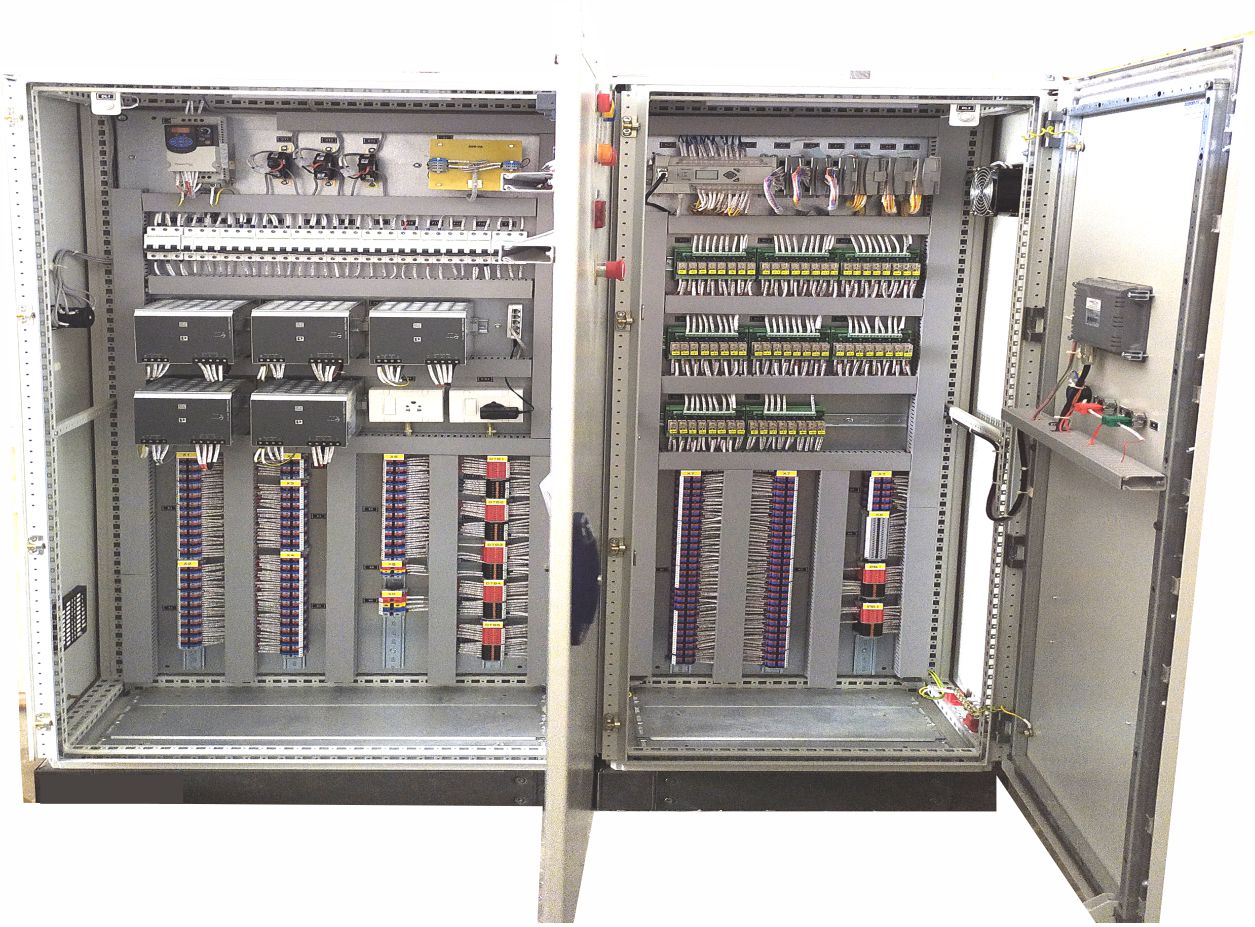

PLC PANEL

- Equipped with PLC Modules, HMI Display, Switchgear etc. Colour Coded wiring as per the IO requirement for easy troubleshooting

CONTROL DESK & REMOTE BOX

- Trouble free performance, sturdy construction longer service life, user-friendly operation, Easy to operate, Durable, Abrasion resistant